-

WHATSAPP

WHATSAPP -

INS

INS -

WECHAT

WECHAT

Wholesale CNC Lathe Machine: Key Benefits For Manufacturing Efficiency

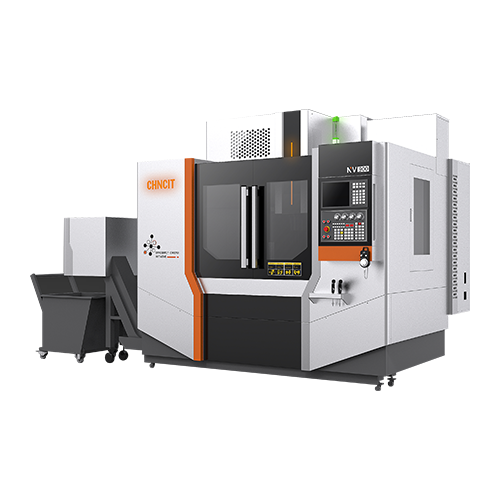

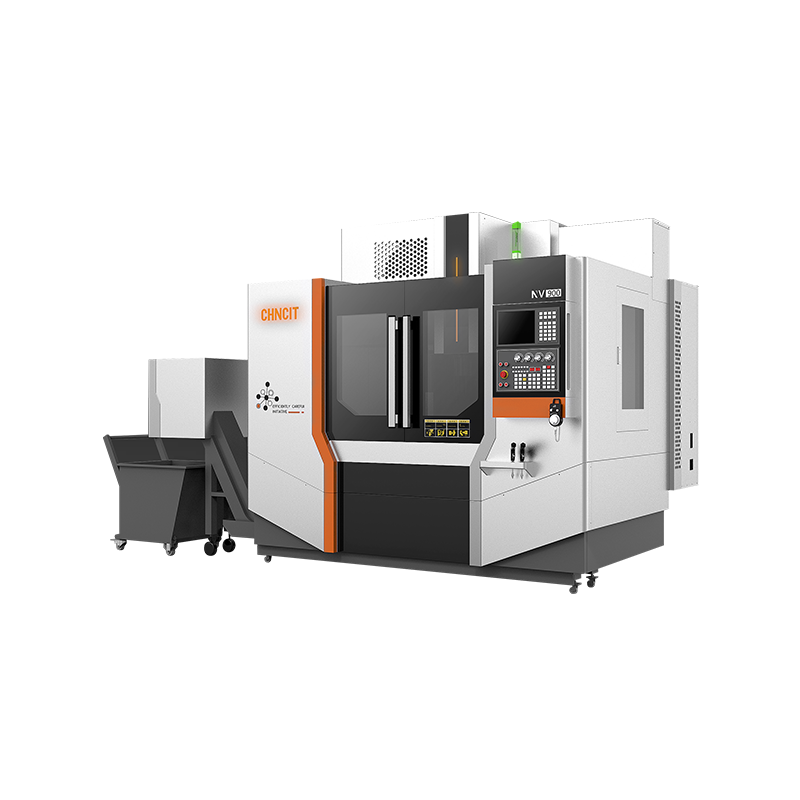

Wholesale CNC Lathe Machine Milling Service Factory Manufacturer

In today's fast-paced manufacturing world, efficiency is key to staying competitive. One of the primary tools that help manufacturers streamline their operations and enhance productivity is the CNC lathe machine. When purchased in bulk through wholesale suppliers, these machines offer significant advantages that can greatly impact the efficiency of production lines. A Wholesale CNC Lathe Machine can provide manufacturers with advanced technology, greater precision, and cost savings, ultimately improving overall performance.

A Wholesale CNC Lathe Machine offers a wide range of applications, from precision machining of metals to the production of intricate components for a variety of industries, including automotive, aerospace, and medical. The core benefit of choosing a wholesale option is the availability of these high-performance machines at a lower cost per unit, making it a more affordable choice for manufacturers who need to purchase multiple units. This not only helps reduce operational costs but also ensures that businesses can equip their production facilities with reliable, cutting-edge technology.

One of the more significant advantages of a Wholesale CNC Lathe Machine is its ability to enhance production speed. These machines are designed to automate many of the manual processes traditionally involved in machining. For example, once set up, a CNC lathe can continuously run without requiring much intervention from operators. This reduction in human labor not only boosts output but also less the risk of human error, which is crucial in industries where precision is a must.

Another key benefit of a Wholesale CNC Lathe Machine is its precision. CNC lathes are renowned for their ability to produce highly accurate and consistent parts. Whether the task involves turning, drilling, or milling, the digital controls allow for fine-tuned adjustments to ensure that every component meets exact specifications. This precision is especially valuable when working with complex designs or high-tolerance components, where even a small deviation could advance to costly errors. With a Wholesale CNC Lathe Machine, manufacturers can rely on consistency, which in turn reduces the need for rework and scrap material, saving time and resources.

Furthermore, the versatility of a Wholesale CNC Lathe Machine makes it an ideal solution for manufacturers who need to produce a wide range of parts. These machines can handle various materials, including metals, plastics, and composites, and can be programmed to execute a variety of tasks with ease. For businesses that need to produce different types of products, a single Wholesale CNC Lathe Machine can often handle multiple tasks, streamlining production and eliminating the need for separate machines for each task. This flexibility enables manufacturers to adjust to changing market demands more effectively and with less capital investment in equipment.

Another critical factor that contributes to the efficiency of the Wholesale CNC Lathe Machine is its ability to reduce setup times. In traditional machining processes, a considerable amount of time is spent adjusting and calibrating machinery to accommodate different parts and tasks. With a CNC lathe, however, operators can easily program the machine to handle multiple jobs without significant downtime. This feature is particularly beneficial in environments where batch production or quick changes in product types are common. Reduced setup time translates to more time spent on actual production, further increasing operational efficiency.

The durability and reliability of a Wholesale CNC Lathe Machine also play a role in enhancing manufacturing efficiency. These machines are built to withstand heavy use and deliver consistent performance over extended periods. By investing in wholesale CNC lathes, manufacturers ensure that their equipment remains operational for longer, reducing the need for frequent maintenance or replacement. This reliability contributes to a smoother production flow and less downtime, helping businesses meet tight deadlines and fulfill customer orders on time.

Moreover, the integration of CNC lathe machines into a facility's manufacturing process can advance to greater worker safety. With the automation of many tasks, there is less direct interaction between operators and heavy machinery. This reduction in human-machine interaction not only decreases the likelihood of workplace accidents but also allows operators to focus on more critical tasks that require human expertise. A Wholesale CNC Lathe Machine can therefore contribute to a safer working environment, which is essential for maintaining productivity and reducing costs associated with workplace injuries.

In terms of scalability, a Wholesale CNC Lathe Machine provides businesses with the flexibility to expand their operations. As production demands increase, manufacturers can purchase additional units of the same machine at wholesale prices, ensuring uniformity across their fleet. This scalability enables companies to increase output without having to overhaul their existing production systems, making growth more manageable and cost-effective.

Finally, purchasing a Wholesale CNC Lathe Machine also offers a strategic advantage in terms of inventory management. Since these machines are designed for longevity and reliability, manufacturers can rely on them for long periods before needing to replace or upgrade. This stability allows for better forecasting and planning in terms of production schedules, inventory control, and resource allocation, further improving efficiency in the overall manufacturing process.

In conclusion, a Wholesale CNC Lathe Machine is an invaluable asset for any manufacturer seeking to improve production efficiency. By offering speed, precision, versatility, and cost savings, these machines help businesses optimize their operations and stay competitive in today's market. The ability to purchase these machines wholesale further enhances their affordability, allowing manufacturers to invest in high-quality equipment without exceeding their budget. With a Wholesale CNC Lathe Machine, manufacturers can look forward to enhanced productivity, lower costs, and a more streamlined production process.