-

WHATSAPP

WHATSAPP -

INS

INS -

WECHAT

WECHAT

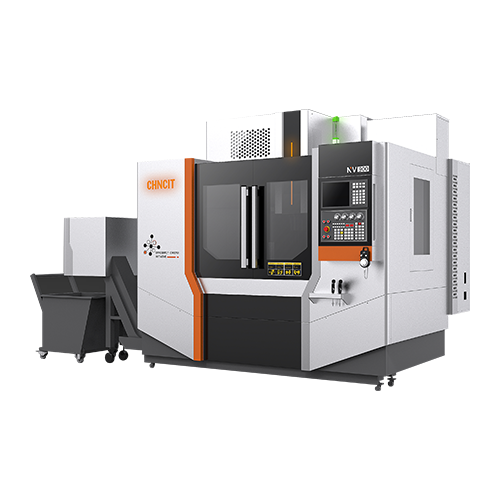

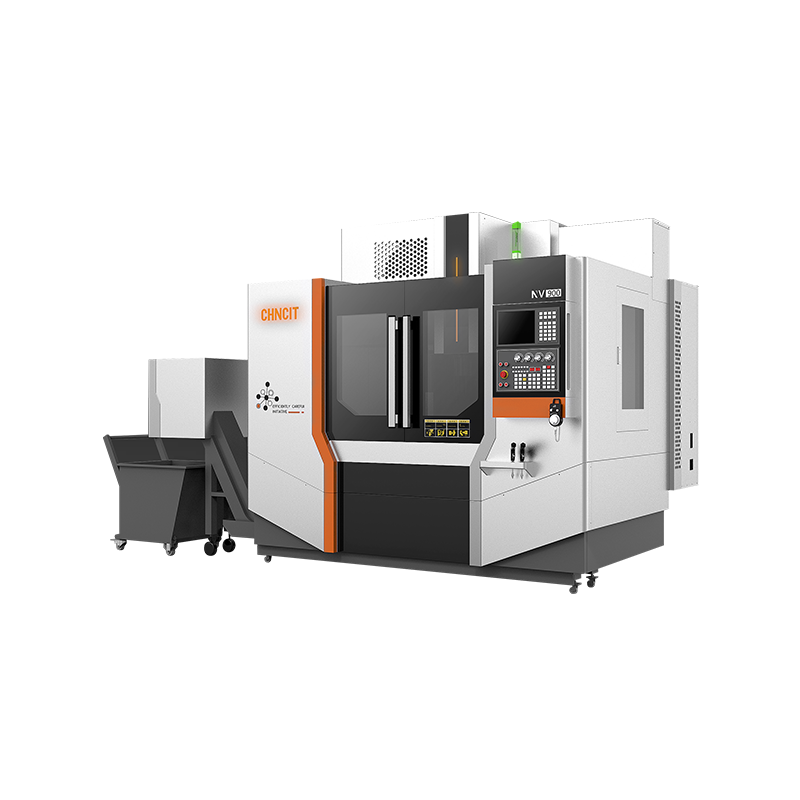

The Powerhouse of Heavy Duty Digital CNC Mill Turn Lathe Machines

A Heavy Duty Digital CNC Mill Turn Lathe Machine is an advanced piece of equipment designed to perform a wide range of machining operations with high accuracy. It is equipped with a computer-controlled system that interprets programmed instructions to control the machine's movements, ensuring precision in the final product.

1. Versatility: The ability to perform both milling and turning operations on the same machine makes it a highly versatile tool in the workshop.

2. Precision: Digital controls and advanced software ensure that the machine can achieve high levels of precision, which is crucial for intricate parts manufacturing.

3. Heavy Duty Construction: Built to withstand the rigors of heavy-duty machining, these machines are typically constructed with robust materials to ensure longevity and stability.

4. User Interface: Modern CNC machines come with user-friendly interfaces that simplify the programming and operation process, making them accessible to a broader range of operators.

5. Automation: Automated tool changers and other features reduce the need for manual intervention, streamlining the production process.

The Heavy Duty Digital CNC Mill Turn Lathe Machine is used across various industries for a multitude of applications:

Aerospace: For the production of complex and precise components used in aircraft and spacecraft.

Automotive: In the manufacturing of engine parts, transmission components, and other intricate parts.

Medical: For the production of surgical instruments and precision medical devices.

Defense: In the creation of high-precision components for military equipment.

General Engineering: For a wide range of machining needs in various engineering projects.

Benefits of Using a CNC Mill Turn Lathe Machine:

1. Increased Productivity: Automation reduces the time spent on manual operations, pilot to faster production rates.

2. Reduced Labor Costs: With less reliance on manual labor, companies can save on labor costs.

3. Improved Quality: The precision of CNC machines ensures consistent quality across all products.

4. Customization: The ability to program specific instructions allows for the creation of customized parts with ease.

5. Reduced Material Waste: Precise cutting reduces the amount of material wasted during the machining process.

While the benefits are numerous, there are also challenges associated with the use of Heavy Duty Digital CNC Mill Turn Lathe Machines:

1. High Initial Cost: The investment required to purchase and install a CNC machine can be substantial.

2. Training: Operators need to be trained to use complex software and controls effectively.

3. Maintenance: Regular maintenance is required to ensure the machine operates at peak performance.

4. Programming Complexity: Creating programs for complex parts can be time-consuming and requires expertise.

5. Technology Updates: Keeping up with the latest technological advancements can be costly and challenging.

As technology continues to evolve, so too does the Heavy Duty Digital CNC Mill Turn Lathe Machine. Future developments are likely to focus on:

Enhanced Precision: Further improvements in accuracy and repeatability.

Intelligent Systems: Integration of AI to predict and correct potential errors during the machining process.

Sustainability: Developments in energy efficiency and the use of sustainable materials.

Connectivity: IoT (Internet of Things) integration for remote monitoring and control.

The Heavy Duty Digital CNC Mill Turn Lathe Machine is a powerful tool in the manufacturing industry, offering a combination of versatility, precision, and efficiency. While there are challenges associated with its use, the benefits it provides in terms of productivity, quality, and customization make it an invaluable asset for many businesses.