-

WHATSAPP

WHATSAPP -

INS

INS -

WECHAT

WECHAT

Understanding the Center Point Drill Hole

A center point drill hole is a small, accurately positioned hole created at the center of a workpiece. This hole is often used as a reference or starting point for larger drilling operations. The purpose of the center point drill hole is to ensure that subsequent drilling is centered and aligned, which helps in maintaining the precision and integrity of the final product.

The process typically involves using a center drill, a specialized tool designed to create a conical hole with a pointed end. This conical shape guides larger drill bits and helps prevent them from wandering off-center during drilling.

Center point drill holes are used in various industries and applications where precision is crucial. Some common applications include:

Machining and Manufacturing: In metalworking and machining, center point drill holes are often used to prepare workpieces for further processing. They provide a precise starting point for larger drills, which is essential for producing accurate and high-quality components.

Woodworking: In woodworking, center point drill holes are used for tasks such as drilling pilot holes for screws or dowels. They ensure that the screws or dowels are positioned correctly and are aligned properly, which is important for the strength and stability of the finished product.

Construction: In construction, center point drill holes are used for tasks such as installing anchors or bolts. The precision of the center point drill hole ensures that the anchors or bolts are positioned accurately, which is critical for the structural integrity of the construction.

Several methods can be employed to create center point drill holes, depending on the specific requirements of the task and the type of material being used. Some common methods include:

Manual Drilling: In manual drilling, a center drill is used to create the center point hole by hand. This method is suitable for small-scale projects or situations where precision is not the high priority. Manual drilling requires careful alignment and steady hand control to ensure accurate results.

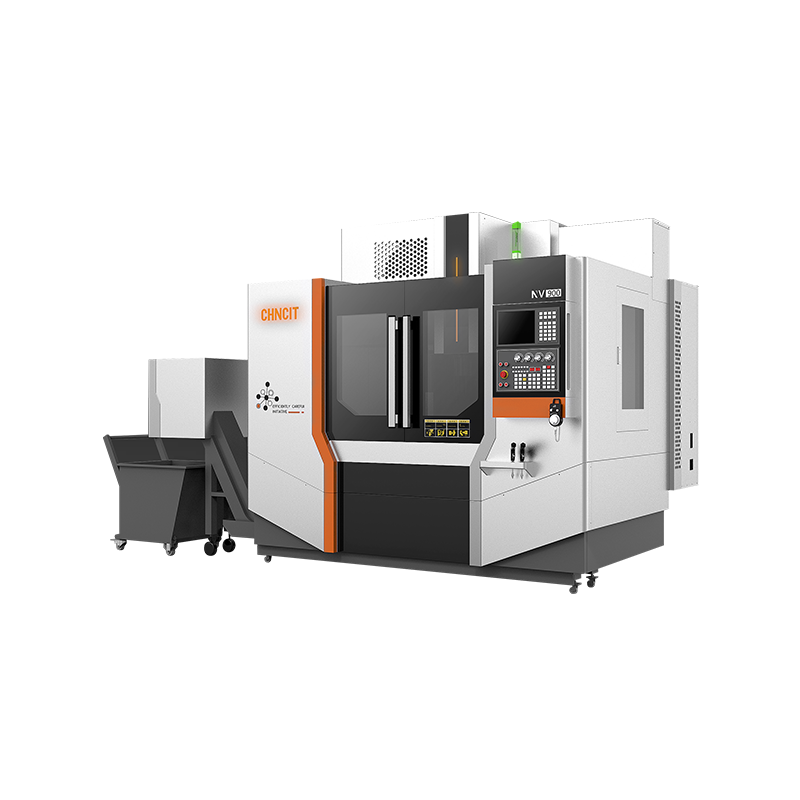

Machine Drilling: Machine drilling involves using a drill press or milling machine to create the center point hole. This method provides greater accuracy and consistency compared to manual drilling. Machine drilling is commonly used in industrial settings where high precision is required.

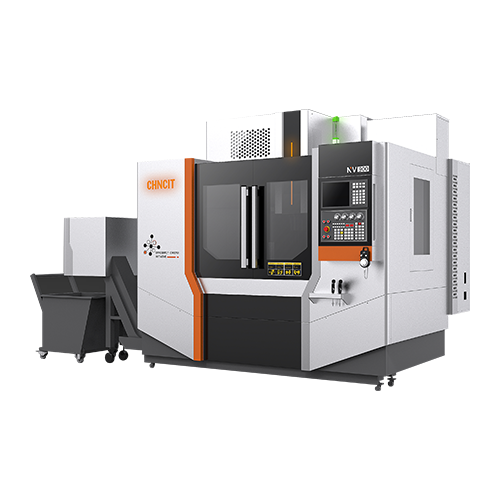

CNC Drilling: CNC (Computer Numerical Control) drilling utilizes automated machines to create center point drill holes with high precision. CNC machines can be programmed to drill multiple holes with exact spacing and alignment, making them ideal for large-scale production and complex projects.

The creation of center point drill holes offers several benefits, particularly in terms of accuracy and efficiency:

Precision: By providing a precise starting point, center point drill holes help ensure that subsequent drilling operations are centered and aligned. This is crucial for producing components with tight tolerances and high-quality finishes.

Alignment: Center point drill holes help in maintaining proper alignment during drilling. This reduces the risk of misalignment or drift, which can lead to defects or compromised functionality in the final product.

Efficiency: The use of center point drill holes can improve the efficiency of the drilling process. By providing a clear guide for larger drills, the center point hole helps to reduce setup times and small errors, pilot to faster and more consistent production.

Reduced Wear: The conical shape of the center point drill hole helps in reducing the wear and tear on larger drill bits. By guiding the drill bit and preventing it from wandering, the center point hole can extend the life of the drilling tools and reduce the need for frequent replacements.

The center point drill hole is a fundamental aspect of precision machining and construction, serving as a guide for subsequent drilling operations. Its applications span various industries, including metalworking, woodworking, and construction, where accuracy and alignment are crucial.