-

WHATSAPP

WHATSAPP -

INS

INS -

WECHAT

WECHAT

Key Considerations for Choosing Between High-Speed and Single-Phase CNC Milling Machines

CNC (Computer Numerical Control) milling machines are pivotal for achieving high-precision and efficient machining. Among these, high-speed CNC precision milling machines and single-phase CNC milling machines serve distinct purposes and cater to different operational needs.

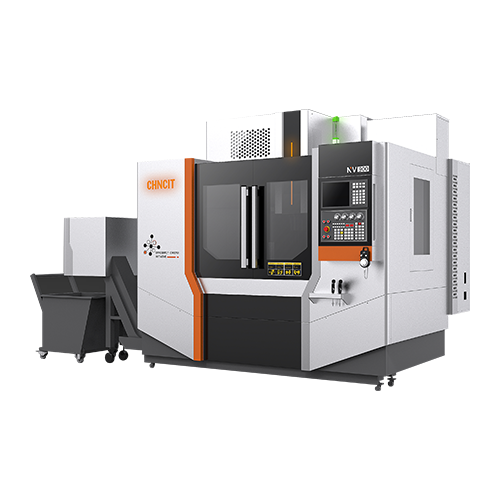

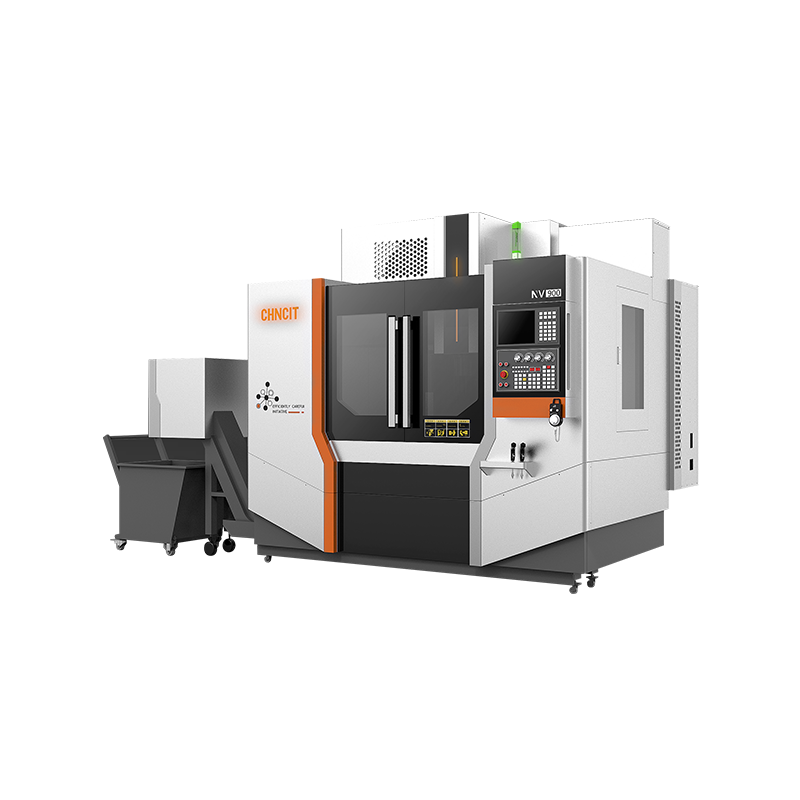

High-speed CNC precision milling machines are designed to perform machining operations at significantly higher speeds compared to standard milling machines. This capability is achieved through advanced technology that allows for rapid tool changes, high spindle speeds, and quick feed rates.

One of the key advantages of high-speed CNC milling machines is their ability to reduce cycle times. The increased spindle speed and rapid movements enable faster material removal, which leads to shorter production runs and higher throughput. This is particularly beneficial in industries where time efficiency is crucial, such as aerospace and automotive manufacturing.

Precision is another hallmark of high-speed CNC milling machines. These machines are engineered to maintain tight tolerances and produce intricate parts with high accuracy. The advanced control systems and precise motor drives ensure that each cut is executed with small deviation, resulting in high-quality finishes and consistent part dimensions.

High-speed CNC machines are often equipped with features such as advanced cooling systems and vibration-damping technologies. These enhancements help manage heat and reduce vibrations, which can negatively impact the quality of the machined parts. Additionally, the integration of sophisticated software and control systems allows for complex geometries and multi-axis machining, expanding the machine's versatility and capabilities.

Single-phase CNC milling machines operate on a standard single-phase electrical supply, making them suitable for environments where three-phase power is not available or practical. These machines are commonly used in smaller workshops, hobbyist setups, and certain manufacturing facilities where high power consumption is not a concern.

The primary advantage of single-phase CNC milling machines is their compatibility with standard electrical systems. This makes them more accessible and easier to install in locations where three-phase power is not feasible. Additionally, single-phase machines are generally more affordable compared to their three-phase counterparts, which can be an important consideration for smaller operations or startups.

Despite their lower power capacity, single-phase CNC milling machines are capable of performing a wide range of machining tasks. They are often used for tasks such as drilling, slotting, and surface milling. The design and functionality of single-phase machines are tailored to handle medium to light machining operations efficiently.

While single-phase CNC milling machines may not offer the same level of speed and power as high-speed models, they can still achieve satisfactory results for many applications. Their control systems are designed to provide precise movements and consistent performance, though they might be limited in handling very large or complex parts.

High-speed CNC precision milling machines are particularly advantageous for applications requiring high productivity and detailed work. Industries that benefit from these machines include aerospace, medical device manufacturing, and high-precision engineering. The ability to work at high speeds and maintain precision makes these machines suitable for producing complex parts with tight tolerances.

On the other hand, single-phase CNC milling machines are well-suited for smaller-scale operations and less demanding tasks. They are often employed in educational settings, prototype development, and small-scale production. Their ease of installation and lower operational costs make them a practical choice for environments where three-phase power is not available.

When selecting between high-speed CNC precision milling machines and single-phase CNC milling machines, several factors should be considered. These include the specific requirements of the machining tasks, available power supply, budget constraints, and the scale of production. For high-volume and complex machining needs, a high-speed CNC machine may be more appropriate. For smaller operations with standard power requirements, a single-phase CNC machine offers a practical and cost-effective solution.