-

WHATSAPP

WHATSAPP -

INS

INS -

WECHAT

WECHAT

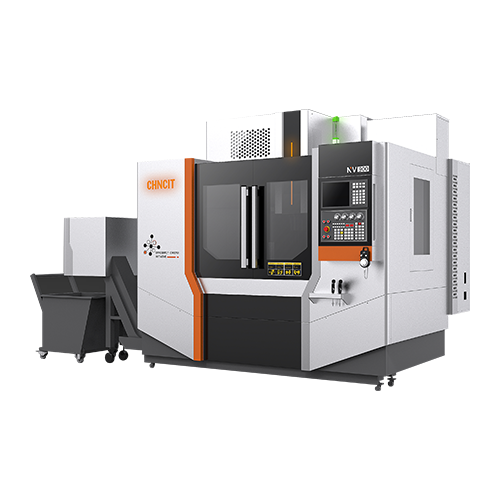

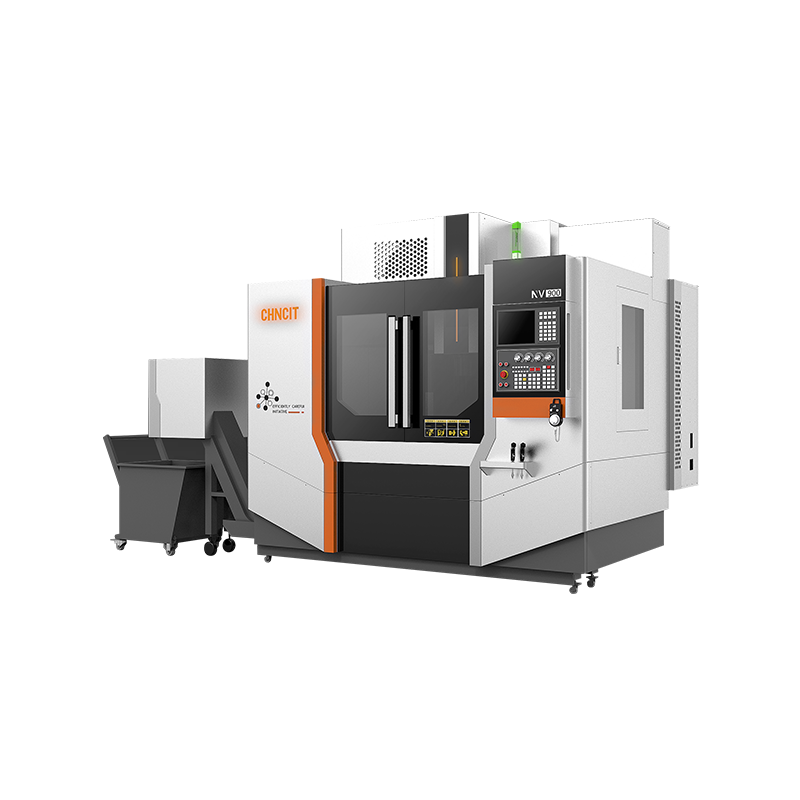

Advanced Automation with Robot CNC Milling Machines

Digital Milling Machines, CNC Router Mills, and Robot CNC Milling Machines are integral components of modern manufacturing and production processes. These machines are designed to perform precise cutting, drilling, and milling operations on a variety of materials, including metal, wood, plastic, and composites.

Digital milling machines, also known as computer numerical control (CNC) mills, are versatile machines that can be programmed to perform a wide range of milling operations. They are controlled by computer software that translates the design into machine code, which the machine then follows to create the desired product.

Applications:

Prototyping: Digital milling machines are often used in the prototyping phase of product development to create functional models.

Mold Making: They are essential in the creation of molds for various industries, including automotive and aerospace.

Medical Devices: Precision parts for medical devices are often milled using these machines.

Benefits:

Precision: Digital milling machines offer high levels of precision, ensuring that parts meet exact specifications.

Efficiency: They can work continuously, reducing the need for manual labor and increasing production speed.

Complexity: Capable of handling complex designs that would be difficult or impossible to create by hand.

CNC router mills are a type of CNC machine that is specifically designed for cutting and shaping materials such as wood, plastic, and aluminum. They are commonly used in woodworking and sign-making industries.

Applications:

Woodworking: Used for creating furniture, cabinetry, and other wooden products.

Sign Making: CNC routers are ideal for cutting out letters and shapes for signs.

Engraving: They can engrave intricate designs on various materials.

Benefits:

Versatility: CNC routers can handle a wide range of materials and are suitable for both rough and fine work.

Customization: They allow for the creation of custom designs, making them ideal for personalized products.

Repeatability: Once a program is created, it can be used repeatedly, ensuring consistency in production.

Robot CNC milling machines combine the precision of CNC technology with the flexibility and adaptability of robotic arms. These machines are capable of performing complex milling operations with a high degree of accuracy and are often used in environments where traditional CNC machines would be limited.

Applications:

Automotive Industry: Robots with CNC milling capabilities are used for the production of complex automotive parts.

Aerospace: They are used for the machining of intricate components that require high precision.

Medical Industry: For the production of prosthetics and other medical devices that require detailed and accurate machining.

Benefits:

Flexibility: Robotic arms can reach areas that are difficult for traditional CNC machines, making them suitable for complex parts.

Adaptability: They can be reprogrammed quickly to adapt to new tasks or changes in production requirements.

Integration: Can be integrated into automated production lines, improving overall efficiency and reducing the need for manual intervention.

Each of these machines plays a crucial role in the modern manufacturing landscape. Digital milling machines offer precision and efficiency, CNC router mills provide versatility and customization, and robot CNC milling machines bring flexibility and adaptability to the production process. As technology continues to advance, these machines are becoming more sophisticated, and capable of handling increasingly complex tasks with greater accuracy and speed. The integration of these machines into production lines is a testament to their value in creating high-quality products that meet the demands of today's consumers.