| Item | Specification | Brand Origin | Brand | |

| Control system | 0I-MF (with tip following) | Japan | FANUC | |

| Spindle Motor | ßil12/12000 | |||

| Servo Motor | X-axis | ßis30/2000 | ||

| Y-axis | ßis30B/2000 | |||

| Z-axis | ßis30/2000 | |||

| A-axis | ßis22/2000 | |||

| B-axis | ßis12/3000 | |||

| Ball Screw | X-axis/Y-axis/Z-axis | 40 | Taiwan | PMI |

| Linear Guide | X-axis/Y-axis/Z-axis | 45 | Taiwan | HIWIN/PMI |

| Screw Coupler | X-axis/Y-axis/Z-axis | BK3/Φ28-Φ35 | Taiwan |

JANETECH |

| Ball Screw Bearing | Japan | NACHI | ||

| Spindles | BT40/12000rpm | Taiwan | POSA | |

| Tool Magazine | BT40/24T | Taiwan | RELIB | |

| Five-Axis Rotary Table | FHR-400CF | Taiwan | TJR | |

| Transformer | 30KWA | Joint Venture | LUHO | |

| Cooling Pump | CBK 4-50/5 | Taiwan | STAIRS | |

| Electrical Components | France | SCHNEIDER | ||

| Pneumatic Components | Japan | SMC | ||

| Lubrication System | China-Japan Joint Venture |

HEGU | ||

| Telescopic Cover | Taiwan | ETEK | ||

| Chip Conveyor | Rear Chip Flush | China | CHNCIT | |

-

WHATSAPP

WHATSAPP -

INS

INS -

WECHAT

WECHAT

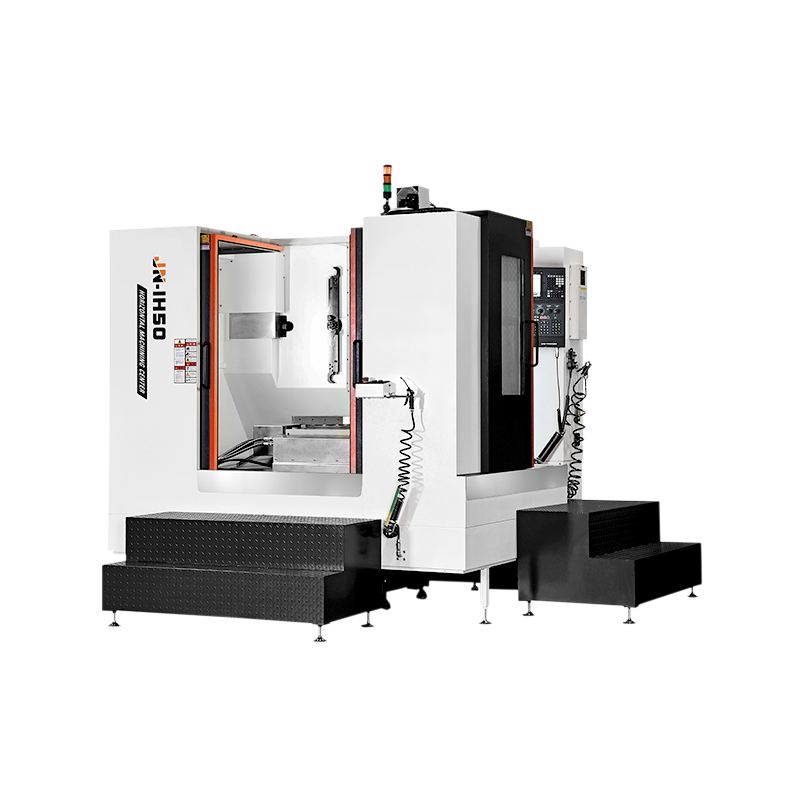

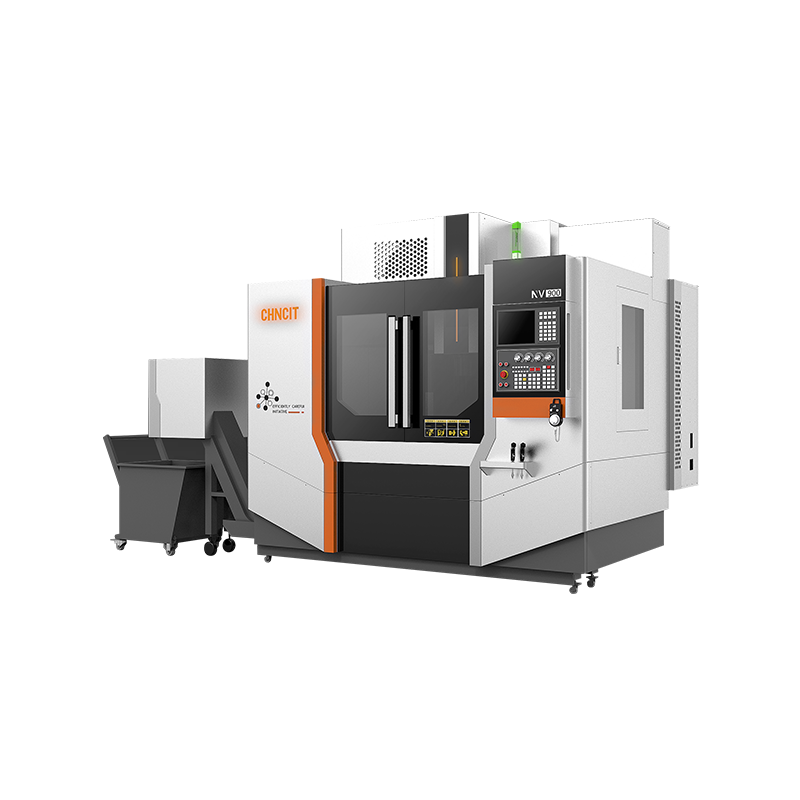

JN-IH50 Horizontal Machining Center

- High-speed, high-rigidity structural design;

- Optimal space utilization and user-friendly operation;

- High production efficiency with great chip evacuation;

- High-speed, high-precision performance control system.

About

Jiangnan CNC Machine Tool Co., Ltd.

Jiangnan CNC Machine Tool Co., Ltd. is situated in the beautiful coastal city of Wenzhou. Established in 2006 with a registered capital of 50 million RMB, our company integrates research, design, manufacturing, and sales into a supply JN-IH50 Horizontal Machining Center in China and JN-IH50 Horizontal Machining Center company production enterprise. We have a standardized plant covering 29,693 square meters and employ over 200 skilled professionals.

Our main products include CNC lathes, vertical machining centers, horizontal machining centers, drilling and tapping centers, and gantry machining centers. Adhering to the principles of "Internationalization, Technological Advancement, and Industrialization," we are dedicated to providing our customers with the most cost-effective products and comprehensive services.

Our main products include CNC lathes, vertical machining centers, horizontal machining centers, drilling and tapping centers, and gantry machining centers. Adhering to the principles of "Internationalization, Technological Advancement, and Industrialization," we are dedicated to providing our customers with the most cost-effective products and comprehensive services.

News

-

When considering an Automatic Lathe Machine, understanding the pre-purchase requirements is essential. Many buyers start by researching CNC...

READ MORE -

Choosing the right CNC Lathe Manufacturer can be a crucial decision for any workshop or industrial facility looking to enhance production ef...

READ MORE -

The CNC drilling and milling machine has become a cornerstone of modern manufacturing operations, offering increased precision, faster produ...

READ MORE -

CNC drilling and milling machine has revolutionized modern manufacturing by providing unparalleled precision and versatility. However, like ...

READ MORE