-

WHATSAPP

WHATSAPP -

INS

INS -

WECHAT

WECHAT

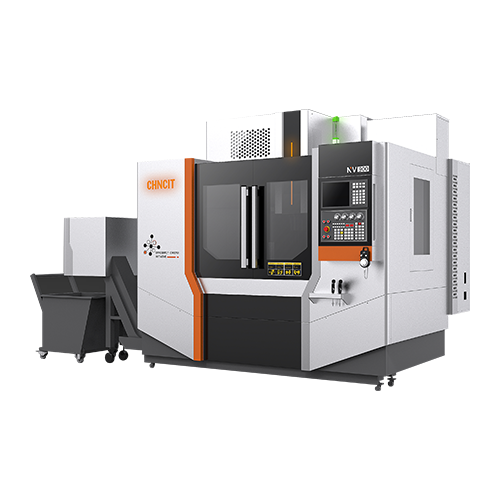

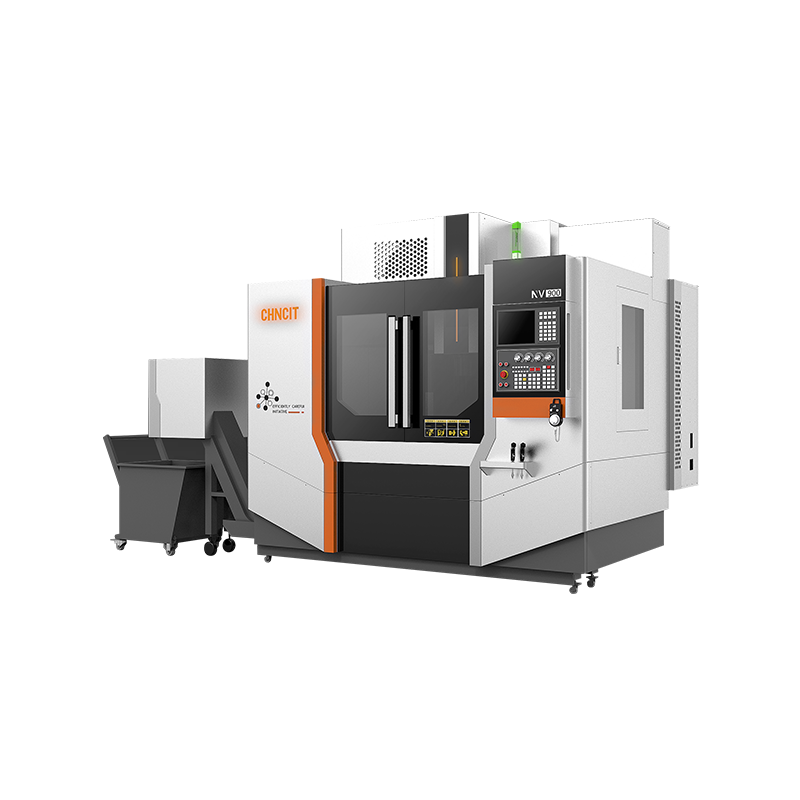

Versatility and Precision of 5-Axis Gantry CNC Machine Machining

A 5-axis gantry CNC machine is a type of computer numerical control (CNC) machine tool that can move a cutting tool or workpiece along five different axes simultaneously. The term gantry refers to the machine's structure, which features a bridge-like framework that spans over the work area. This design provides stability and allows for machining large, complex parts.

The five axes typically include three linear axes (X, Y, and Z) and two rotational axes (A and B). The linear axes move the tool or workpiece in three-dimensional space, while the rotational axes allow for tilting and rotating movements. This combination of movements enables the machine to approach the workpiece from virtually any angle, facilitating the machining of intricate shapes and features.

Key Features of 5-Axis Gantry CNC Machines

Gantry Structure: The gantry design offers high rigidity and stability, essential for maintaining precision during complex machining operations. The structure can support large workpieces and withstand significant cutting forces.

Multi-Axis Control: The ability to move along five axes simultaneously allows for complex machining processes, such as contouring, drilling, and milling, in a single setup. This reduces the need for multiple setups and increases efficiency.

Large Work Area: Gantry CNC machines often feature a spacious work envelope, accommodating large parts or multiple smaller parts in one machining cycle. This is particularly beneficial for industries that require the production of sizable components.

Advanced CNC Systems: Modern 5-axis gantry CNC machines are equipped with sophisticated control systems that offer high precision, real-time monitoring, and advanced programming capabilities. These systems enhance the machine's performance and ease of use.

Tool Changers: Automated tool changers enable the machine to switch between different cutting tools quickly, supporting complex machining tasks without manual intervention. This feature enhances productivity and versatility.

Benefits of 5-Axis Gantry CNC Machining

Enhanced Precision: The multi-axis capability of 5-axis gantry CNC machines ensures high precision and accuracy, making them suitable for applications that demand tight tolerances and detailed features.

Reduced Setup Time: By allowing complex parts to be machined in a single setup, these machines significantly reduce setup time. This not only improves efficiency but also smalls the potential for errors associated with repositioning the workpiece.

Improved Surface Finish: The ability to approach the workpiece from different angles allows for more efficient material removal and better surface finish. This is particularly important for components that require a high-quality finish.

Versatility: 5-axis gantry CNC machines can handle a wide range of materials and part geometries, making them versatile tools for various industries. From aerospace components to medical devices, these machines are capable of machining diverse parts.

Increased Productivity: The combination of reduced setup times, automated tool changing, and efficient machining processes leads to increased productivity. Manufacturers can produce more parts in less time, meeting tight production schedules.

Applications of 5-Axis Gantry CNC Machines

Aerospace Industry: The aerospace sector requires the machining of complex components with high precision. 5-axis gantry CNC machines are used to manufacture aircraft parts, such as turbine blades, structural components, and engine parts.

Automotive Industry: In the automotive industry, these machines are employed to produce intricate parts like engine blocks, transmission components, and chassis parts. The precision and efficiency of 5-axis machining ensure high-quality automotive parts.

Medical Device Manufacturing: The medical device industry demands the production of complex and precise components, such as implants, surgical instruments, and prosthetics. 5-axis gantry CNC machines meet these requirements by providing the necessary accuracy and surface finish.

Mold and Die Making: The mold and die industry relies on 5-axis machining to create detailed molds and dies used in manufacturing processes. These machines can handle the intricate geometries and fine details required for high-quality molds.

5-axis gantry CNC machines represent a significant technological advancement in the machining industry. Their ability to perform complex machining tasks with high precision and efficiency makes them invaluable tools across various sectors, including aerospace, automotive, medical device manufacturing, mold and die making, and the energy sector.