-

WHATSAPP

WHATSAPP -

INS

INS -

WECHAT

WECHAT

Understanding the Roles of CNC Machining Turning

CNC Machining Turning is a manufacturing process that uses a lathe to remove material from a rotating workpiece. This technique is primarily used to create cylindrical parts and components with precise dimensions and surface finishes. The CNC (Computer Numerical Control) system automates the turning process, allowing for intricate designs and complex geometries to be achieved with high accuracy.

CNC Machining Turning is widely used in industries such as aerospace, automotive, and medical devices. It is ideal for producing components like shafts, bushings, and fittings that require tight tolerances and smooth finishes. The ability to handle various materials, including metals, plastics, and composites, makes it a versatile option for many manufacturing applications.

One of the main benefits of CNC Machining Turning is its ability to produce high-precision cylindrical parts efficiently. The automation provided by CNC systems smalls the risk of human error and ensures consistent quality across multiple parts. Additionally, CNC lathes can perform various operations, including drilling, boring, and threading, within a single setup, which improves productivity and reduces the need for multiple machines.

The CNC Mill Drill Machine combines milling and drilling operations within one unit. This type of machine integrates the capabilities of both a milling machine and a drill press, allowing for a range of machining tasks to be performed on a single workpiece. The CNC control system facilitates precise movements and complex operations, enhancing the machine's versatility.

CNC Mill Drill Machines are used in industries that require both milling and drilling functions, such as manufacturing of prototypes, custom parts, and small to medium-sized production runs. They are particularly useful for tasks that involve creating holes, slots, and complex shapes in materials such as metals, plastics, and composites.

The primary advantage of a CNC Mill Drill Machine is its ability to handle multiple machining processes in one setup. This reduces setup time and increases efficiency by small the need to transfer workpieces between different machines. The CNC control system allows for precise and repeatable operations, which ensures consistent quality and reduces the likelihood of errors.

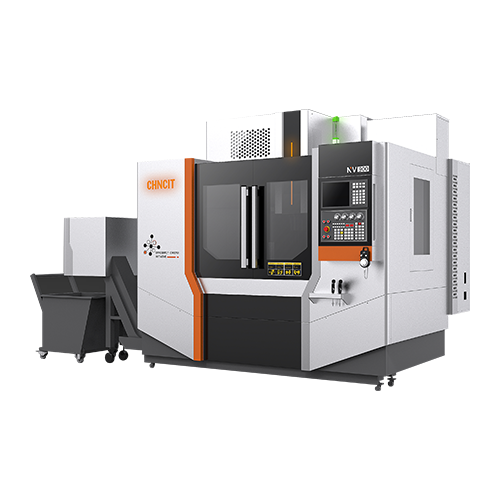

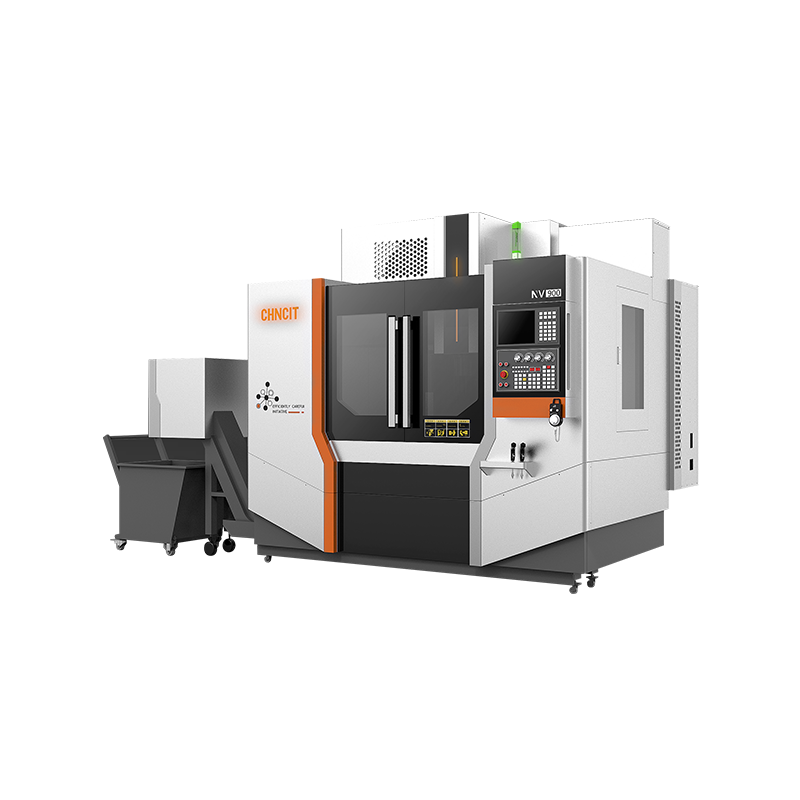

A CNC Milling Machine Center is a sophisticated machine designed for high-precision milling operations. Unlike traditional milling machines, CNC Milling Machine Centers are equipped with advanced features such as tool changers and multi-axis capabilities, which enhance their versatility and productivity. These machines are used for a wide range of milling applications, from simple to highly complex parts.

CNC Milling Machine Centers are commonly used in industries such as aerospace, automotive, and industrial machinery. They are ideal for producing complex parts with tight tolerances, including components with multiple features and intricate geometries. The ability to perform multi-axis milling allows for the creation of parts with complex shapes and high precision.

The CNC Milling Machine Center offers several advantages, including high precision, efficiency, and flexibility. The machine's advanced features, such as automatic tool changers and programmable functions, enable it to handle a wide variety of milling tasks with small manual intervention. This automation improves productivity and reduces the likelihood of errors. Additionally, the ability to perform multi-axis milling allows for the creation of complex parts in a single setup, which streamlines the manufacturing process and reduces the need for multiple operations.

CNC Machining Turning, CNC Mill Drill Machines, and CNC Milling Machine Centers each play a significant role in modern manufacturing. CNC Machining Turning is ideal for producing high-precision cylindrical parts, while CNC Mill Drill Machines offer versatility by combining milling and drilling operations in one unit. CNC Milling Machine Centers, with their advanced features and multi-axis capabilities, are suited for complex and high-precision milling tasks.