-

WHATSAPP

WHATSAPP -

INS

INS -

WECHAT

WECHAT

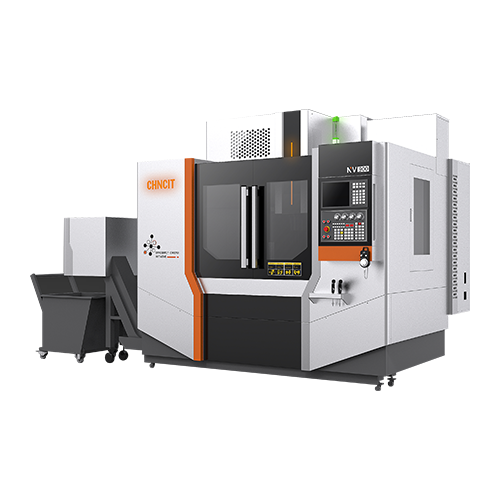

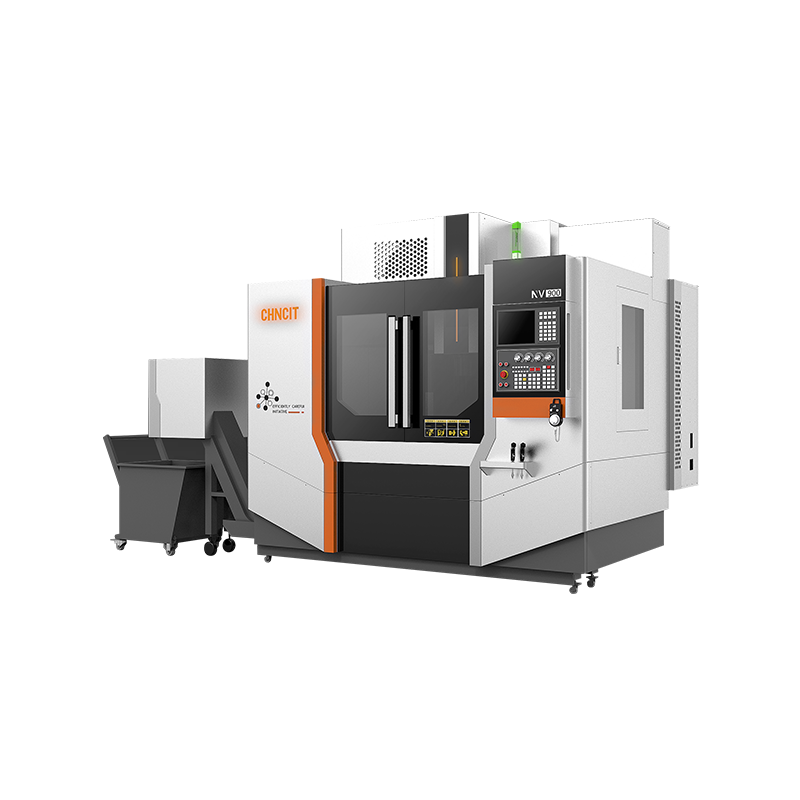

The Versatility of Modern CNC Lathes in Precision Machining

In the precision machining industry, the CNC lathe has become a cornerstone of manufacturing processes. Precision CNC lathes, multi-axis lathes, and table top CNC lathes are examples of technological advancements that have transformed the way parts are produced.

The CNC lathe, or computer numerical control lathe, is a machine tool used for shaping various materials, primarily metals, by cutting, boring, and threading. The advent of CNC technology has revolutionized the lathe's capabilities, allowing for greater precision, efficiency, and versatility in machining operations.

Precision CNC lathes are designed for high-accuracy machining. They are equipped with advanced control systems that allow for complex part designs to be produced with small human intervention. These machines are characterized by:

High Accuracy: Precision CNC lathes are built with high-precision components to ensure that the final product meets stringent tolerances.

Rigidity: The machine's structure is designed to be robust, small vibrations and maintaining stability during operation.

Customizable Tooling: A wide range of tooling options allows for various machining processes to be performed on a single machine.

Multi-axis lathes take the capabilities of CNC lathes a step further by allowing for more complex machining operations. These machines can perform operations on multiple faces of a workpiece simultaneously, reducing the need for secondary operations and setups. Key features of multi-axis lathes include:

Simultaneous Machining: The ability to machine multiple sides of a workpiece at once, increasing efficiency and reducing production time.

Complex Part Production: Suitable for parts with complex geometries that require intricate machining.

Reduced Setup Time: Fewer setups are needed, as more features can be machined in a single operation.

Table top CNC lathes are compact and designed for small to medium-sized workpieces. They are ideal for small-scale production, prototyping, and precision machining in limited spaces. The benefits of table top CNC lathes are:

Compact Size: These machines are designed to fit into smaller workspaces, making them ideal for workshops with space constraints.

Ease of Use: Often featuring user-friendly interfaces, table top CNC lathes are accessible to a wide range of operators.

Cost-Effectiveness: Due to their smaller size and scope, table top CNC lathes are typically more affordable than their larger counterparts.

CNC lathes are used across a variety of industries, including automotive, aerospace, medical, and electronics, for the production of parts such as:

Bearings and Bushings: Precision CNC lathes are ideal for producing these components with tight tolerances.

Aerospace Components: Multi-axis lathes can handle the complex geometries required for aerospace parts.

Medical Implants: Table top CNC lathes are well-suited for the small, precise parts often needed in the medical field.

The benefits of using CNC lathes in manufacturing include:

Increased Productivity: Automated processes reduce downtime and increase output.

Improved Quality: Consistent machining processes result in parts with uniform quality.

Reduced Labor Costs: Less manual intervention is required, lowering labor costs over time.

The evolution of CNC lathes has had a profound impact on the manufacturing industry. Precision CNC lathes, multi-axis lathes, and table top CNC lathes each offer unique advantages that cater to different production needs.

In conclusion, the versatility and precision offered by modern CNC lathes are testament to the progress in manufacturing technology. Whether for large-scale production or intricate, small-scale work, these machines provide a reliable and efficient solution for a wide range of machining applications.