-

WHATSAPP

WHATSAPP -

INS

INS -

WECHAT

WECHAT

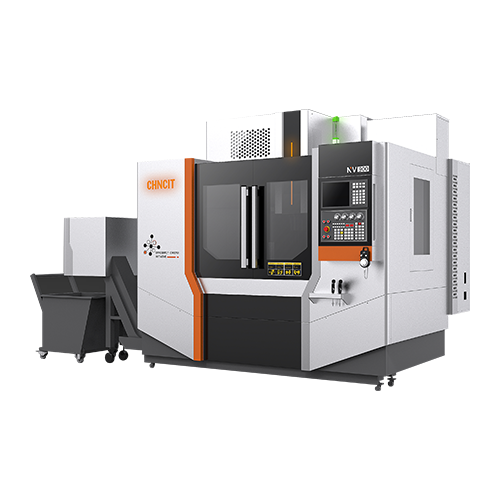

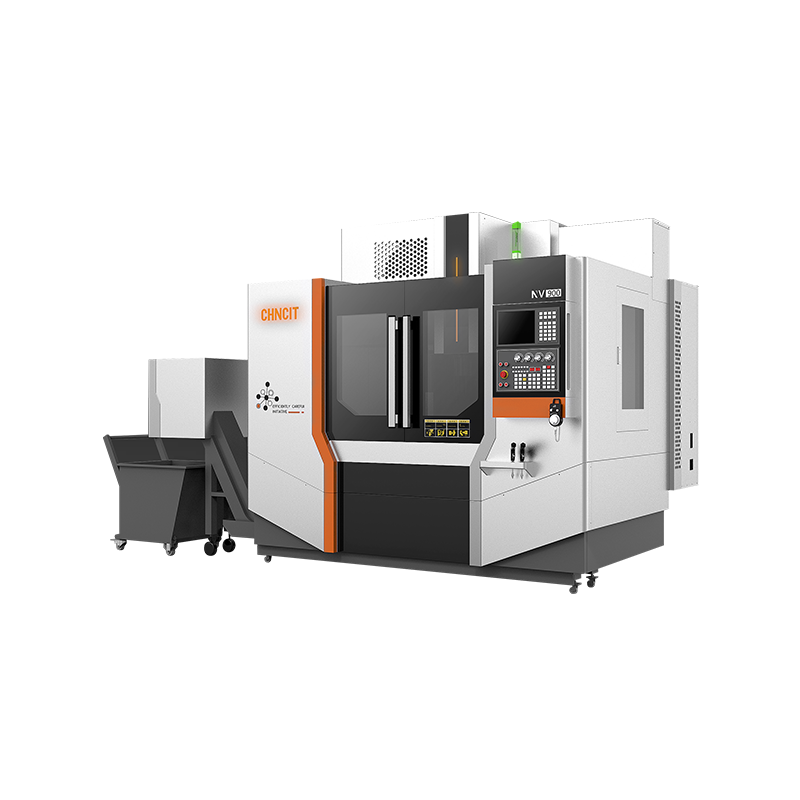

The Impact of CNC Laser Milling Machines

The CNC Laser Milling Machine combines the principles of laser cutting and milling within a single unit. This technology is advantageous for high-precision tasks requiring both cutting and shaping of materials. The machine uses a focused laser beam to cut or engrave materials, while a milling spindle performs additional shaping tasks.

Applications: CNC Laser Milling Machines are particularly useful in industries such as aerospace, automotive, and electronics. They can handle materials ranging from metals to plastics with high precision. This versatility makes them suitable for creating intricate parts and components that require fine details and tight tolerances.

Advantages: One of the primary benefits of CNC Laser Milling Machines is their ability to perform detailed work with small material waste. The laser cutting process is precise, which reduces the amount of material needed and ensures that the final product meets exact specifications. Additionally, these machines often have automated functions that improve production speed and reduce the need for manual intervention.

The CNC Plano Miller is designed for large-scale milling operations, particularly useful for machining large and heavy workpieces. Unlike traditional milling machines, which typically handle smaller components, the CNC Plano Miller features a robust design capable of accommodating substantial sizes and weights. This makes it suitable for industries such as heavy machinery, shipbuilding, and structural engineering.

Applications: This machine is ideal for tasks such as machining large frames, bases, and other substantial parts that require precise milling across their surfaces. It can be used for both horizontal and vertical milling, providing versatility in handling different milling operations.

Advantages: The main advantage of the CNC Plano Miller is its capacity to handle large workpieces with high precision. Its sturdy construction ensures stability during the milling process, which helps achieve accurate dimensions and surface finishes. Additionally, the CNC control system allows for programmable operations, improving efficiency and consistency in production.

The CNC Mill Turn Lathe combines the functionalities of both milling and turning in a single machine. This integration allows for complex machining tasks to be performed in one setup, reducing the need for multiple machines and setups. The CNC Mill Turn Lathe is equipped with both milling and turning spindles, enabling it to execute a wide range of operations on a single workpiece.

Applications: This machine is commonly used in industries where complex parts with both turning and milling features are required. It is suitable for producing components such as automotive parts, aerospace components, and precision medical instruments. The ability to perform multiple operations in a single machine enhances production efficiency and reduces the overall manufacturing time.

Advantages: The CNC Mill Turn Lathe offers several advantages, including the reduction of setup times and improved accuracy. By performing both turning and milling operations in one machine, manufacturers can achieve more complex geometries and tighter tolerances. This consolidation of processes also smalls the risk of errors and misalignments that can occur when transferring workpieces between different machines.

The CNC Laser Milling Machine, CNC Plano Miller, and CNC Mill Turn Lathe each play a crucial role in modern manufacturing. The CNC Laser Milling Machine excels in precision cutting and engraving, while the CNC Plano Miller is designed for large-scale milling operations. The CNC Mill Turn Lathe integrates milling and turning functionalities, providing a versatile solution for complex machining tasks.