-

WHATSAPP

WHATSAPP -

INS

INS -

WECHAT

WECHAT

Applications and Features of CNC Router Face Mills

CNC Plano Miller machines are designed for precision machining of large workpieces. These machines are characterized by their ability to handle extensive milling operations on flat surfaces, utilizing computer numerical control (CNC) for automation and precision.

Key Features:

Large Work Area: CNC Plano Miller machines have a significant working area, allowing for the machining of large components.

High Precision: The CNC system ensures precise control over the milling operations, pilot to high-quality results.

Versatility: These machines can perform a variety of milling tasks, including facing, drilling, and slotting.

CNC Plano Miller machines are widely used in industries that require the machining of large and heavy components, such as the aerospace, automotive, and heavy machinery industries. They are ideal for tasks like machining large castings, structural components, and large metal sheets.

CNC Profile Machining Centers are specialized for the machining of profiles and complex shapes. These centers are equipped with advanced CNC systems that allow for intricate and detailed work, making them suitable for high-precision applications.

Key Features:

Complex Shaping: The CNC system enables the machining of complex profiles and shapes with high accuracy.

Multi-Axis Control: These machines often have multi-axis capabilities, allowing for the machining of complex geometries.

Efficiency: Automation through CNC increases productivity and reduces manual intervention.

CNC Profile Machining Centers are commonly used in industries such as aerospace, automotive, and mold making. They are ideal for producing complex parts, such as turbine blades, automotive body panels, and intricate mold components.

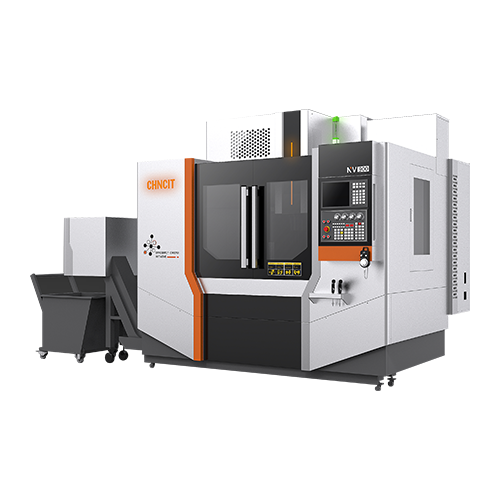

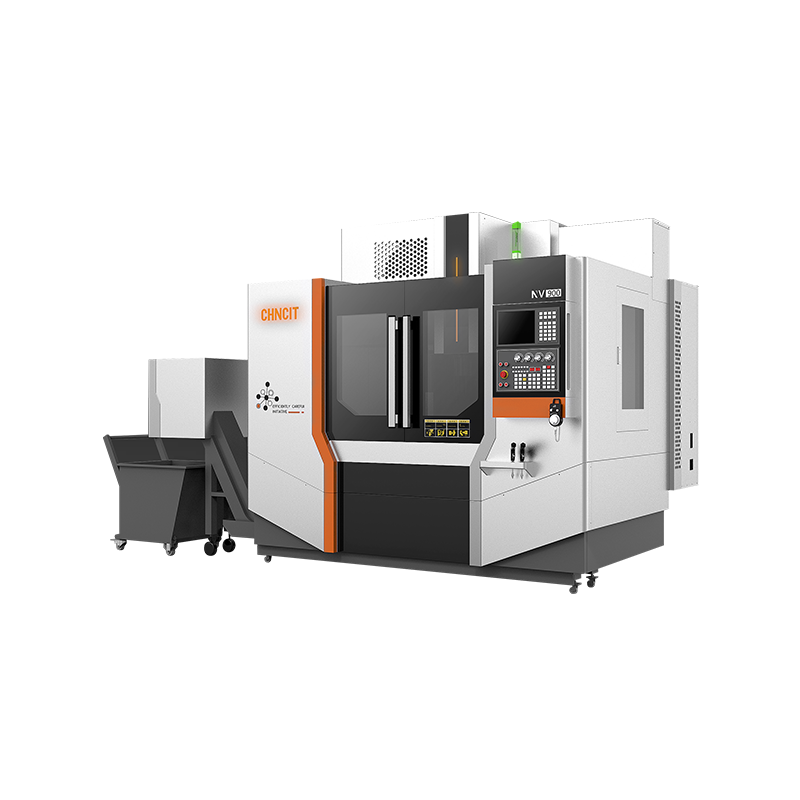

CNC Router Face Mills are designed for high-speed milling operations on flat surfaces. These machines are known for their efficiency and precision, making them suitable for a variety of milling tasks.

Key Features:

High Speed: CNC Router Face Mills operate at high speeds, increasing productivity and reducing machining time.

Precision Milling: The CNC system ensures precise control over the milling process, resulting in high-quality finishes.

Versatility: These machines can handle various materials, including wood, plastics, and metals.

CNC Router Face Mills are used in a range of industries, including woodworking, plastics, and metalworking. They are ideal for tasks such as surface finishing, contouring, and cutting large sheets into precise shapes.

When choosing between CNC Plano Miller machines, CNC Profile Machining Centers, and CNC Router Face Mills, several factors should be considered:

Type of Workpiece: CNC Plano Miller machines are suitable for large and flat workpieces, while CNC Profile Machining Centers are designed for complex profiles and shapes. CNC Router Face Mills are ideal for high-speed milling on flat surfaces.

Material: The choice of machine can also depend on the material being machined. CNC Router Face Mills are versatile and can handle a range of materials, while CNC Plano Miller machines and CNC Profile Machining Centers are often used for metals and high-precision components.

Complexity of Task: For intricate and detailed work, CNC Profile Machining Centers are the good choice due to their advanced capabilities. For large-scale flat-surface machining, CNC Plano Miller machines are more appropriate. For high-speed and efficient flat surface milling, CNC Router Face Mills are suitable.

Production Volume: CNC Router Face Mills, with their high-speed capabilities, is ideal for high-volume production. CNC Profile Machining Centers and CNC Plano Miller machines are better suited for specialized, high-precision tasks.

CNC Plano Miller machines, CNC Profile Machining Centers, and CNC Router Face Mills each serve distinct purposes and are suited to different types of milling tasks. CNC Plano Miller machines are ideal for large and heavy workpieces, CNC Profile Machining Centers excel in complex shaping and profile machining, and CNC Router Face Mills is good for high-speed flat surface milling.